Designed for industrial performance and proven reliability, it adapts to diverse feedstocks and carbon content requirements while maintaining exceptional efficiency.

Its modular and scalable design allows seamless deployment worldwide, enabling durable carbon removal (CDR) credits and meaningful climate benefits at industrial scale.

The carbonization process generates a significant surplus of syngas, creating excess energy within the system.

Part of this energy is recovered by the DryFX™ unit for biomass drying, while the remaining syngas can be condensed into liquid bio-oil using Airex Energy’s equipment or repurposed for district heating, electricity or directly integrated in a local process (to replace natural gas for example).

When biochar is applied to soils, durable carbon removal (CDR) credits are generated and tracked, ensuring measurable and lasting climate impact, while creating additional revenue for the project.

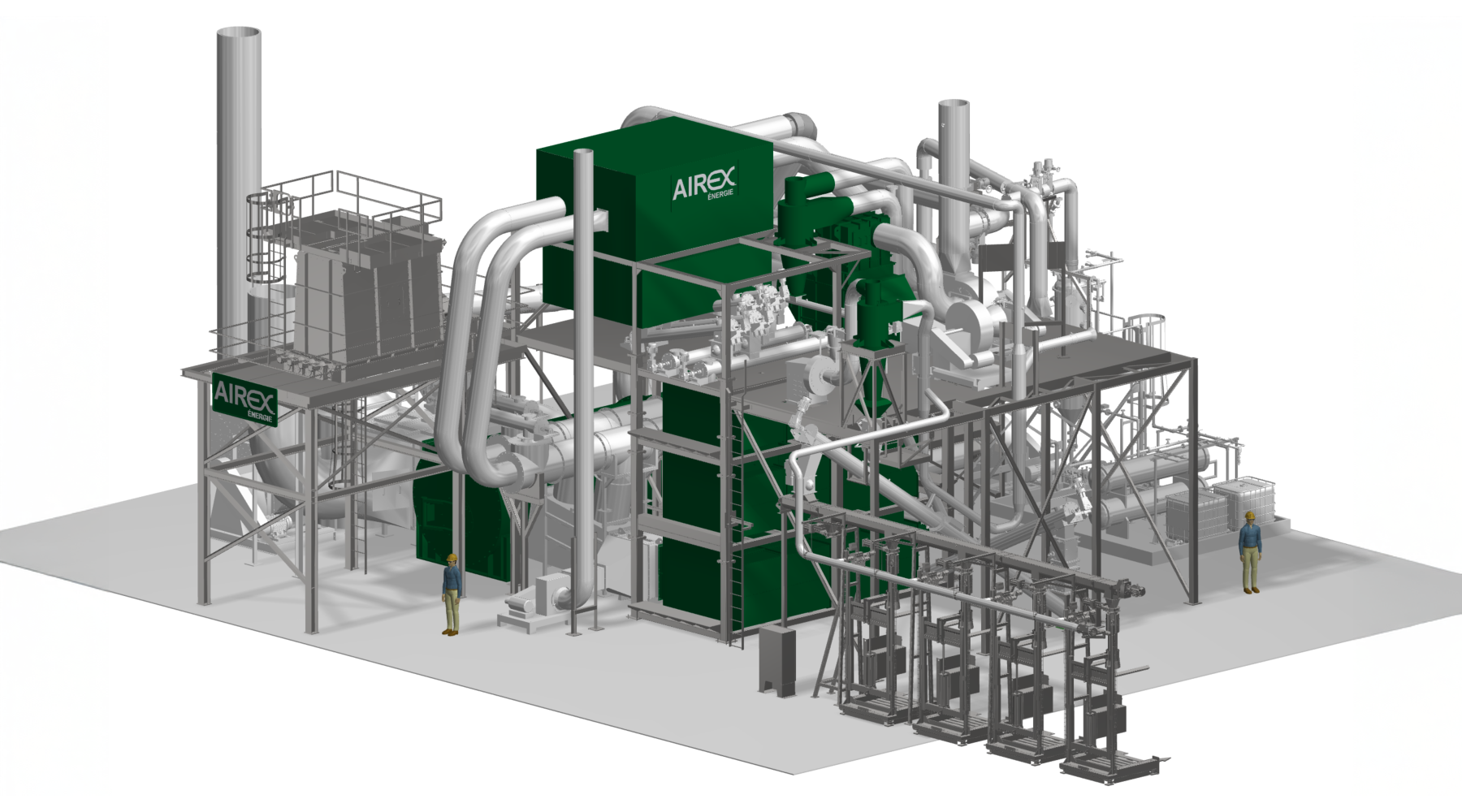

Conditioning cyclonic reactor

Carbonization chamber

Combustion chamber

Cyclonic reactors serve as the initial treatment step, receiving the biomass pneumatically. In these reactors, the feedstock comes into direct contact with hot flue gases.

This flash heating finalizes the drying phase, rapidly reducing the moisture content to near-zero levels.

The short residence time ensures material stability before entering the next stage while preserving the structure of the biomass for optimal carbonization.

Dried biomass is then directed into carbonization screws located inside the insulated carbonization chamber.

These screws are externally heated through indirect contact with hot air circulating around them within the chamber.

In this oxygen-deprived environment, the biomass undergoes thermal decomposition, converting into high-carbon biochar and biocarbon.

During this stage, syngas (torr-gas) generated by the decomposition process is separated from the solid biochar within the screw conveyors and routed to the combustion chamber for energy recovery.

the syngas is then mixed with air and burned, and this syngas-air mixture becomes the fuel that provides energy for the carbonization process.

The combustion chamber acts as the thermal oxidizer of the CarbonFX-HT™ system. Here, the recovered syngas is combusted with controlled air addition.

The resulting thermal energy is used to heat the carbonization chamber and supply hot gases to the cyclonic reactors.

Any excess energy generated by the process is recovered and utilized for feedstock drying or further valorized through conversion into high-value products.

(%FC, NCV, etc)

| Model | CarbonFX-HT™ |

|---|---|

| Technology | Carbonization |

| Process temperature (°C) | 500-600 |

| Operating mode | Continuous |

| Heating method | Indirect |

| Reactor type | Screw |

| Output product | Biochar & Biocarbon (metallurgical biochar) |

| Product format | Coarse powder |

| Total carbon content | + 70% |

| Energy density (MJ/kg, db) | 25-35 |

| Performance | Industrial volume (24/7 operation) |

| Yield | 25% - 35% |

| Input production capacity (kg/h, db) | 4000 |

| Output production capacity (kg/h, db) | 1000-3000 |

| Scalability | Yes (modular) |

| Waste (liquid or solid) | None |

| Process automation | Advanced |

| Feedstock compatibility | Very flexible |

| By-products | Excess energy (syngas) |

| Carbon credits | Yes (Biochar only) |

| Certifications | Yes (Biochar only) |

| Footprint size (L x W x H) | 22m x 22m x 10m |