Renewable – Sustainably-managed sources of biomass can provide fuel indefinitely.

Readily available – A significant amount of biomass is available in most regions of North America.

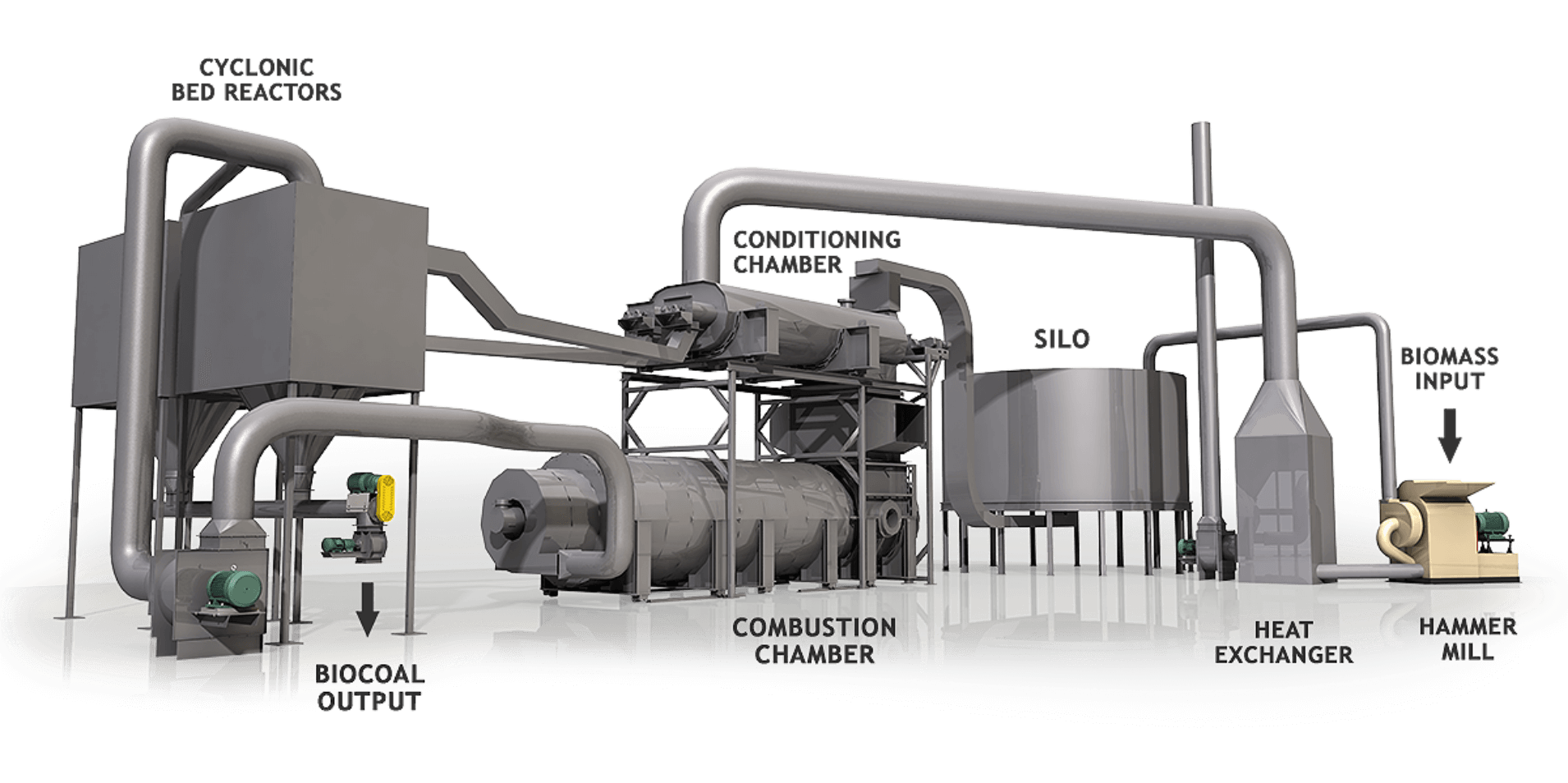

CarbonFX technology transforms any type of biomass into value-added green carbon products.

Torrefaction - Carbonization

Biomass is perhaps the oldest source of energy in the world.

Biomass energy is derived from recently living organic matter such as sawmill waste, logging residues, low-grade biomass and agricultural residues.

Renewable – Sustainably-managed sources of biomass can provide fuel indefinitely.

Readily available – A significant amount of biomass is available in most regions of North America.

The use of fossil fuels releases carbon from ancient pools that cannot be replenished. Biomass, however, contains carbon extracted from the atmosphere. Through photosynthesis, the carbon contained in the atmosphere in a gaseous form is sequestered in a solid form in plants and trees. The carbon is then released again to the atmosphere through the natural decomposition or combustion of the biomass. Therefore, there is no net addition of carbon to the atmosphere when biomass is used as a fuel to produce energy or heat.

Biomass must be sourced on a sustainable basis in order to be considered renewable. According to the United Nations Framework Convention on Climate Change (UNFCCC), biomass from forest lands is considered renewable if sustainable management practices are undertaken on these forest lands to ensure that the level of carbon stock does not systematically decrease over time.

Head Office

2500 Bernard-Lefebvre Street

Laval, Québec, Canada, H7C 0A5

450.661.6498

Bécancour Plant

103-4170 La Prade Blvd.

Bécancour, Québec, Canada, G9H 0B6