The CarbonFX™ produces torrefied material with unmatched quality, consistency, and homogeneity, using our cyclonic reactor patented technology. The resulting biocoal can be used directly as a fine powder or pelletized for specific applications.

Once pelletized, biocoal is dust-free, non-hazardous, and safe to handle and transport worldwide. Durable and weather-resistant, it can be stored outdoors and easily integrated into existing processes, offering a clean & reliable alternative to fossil coal.

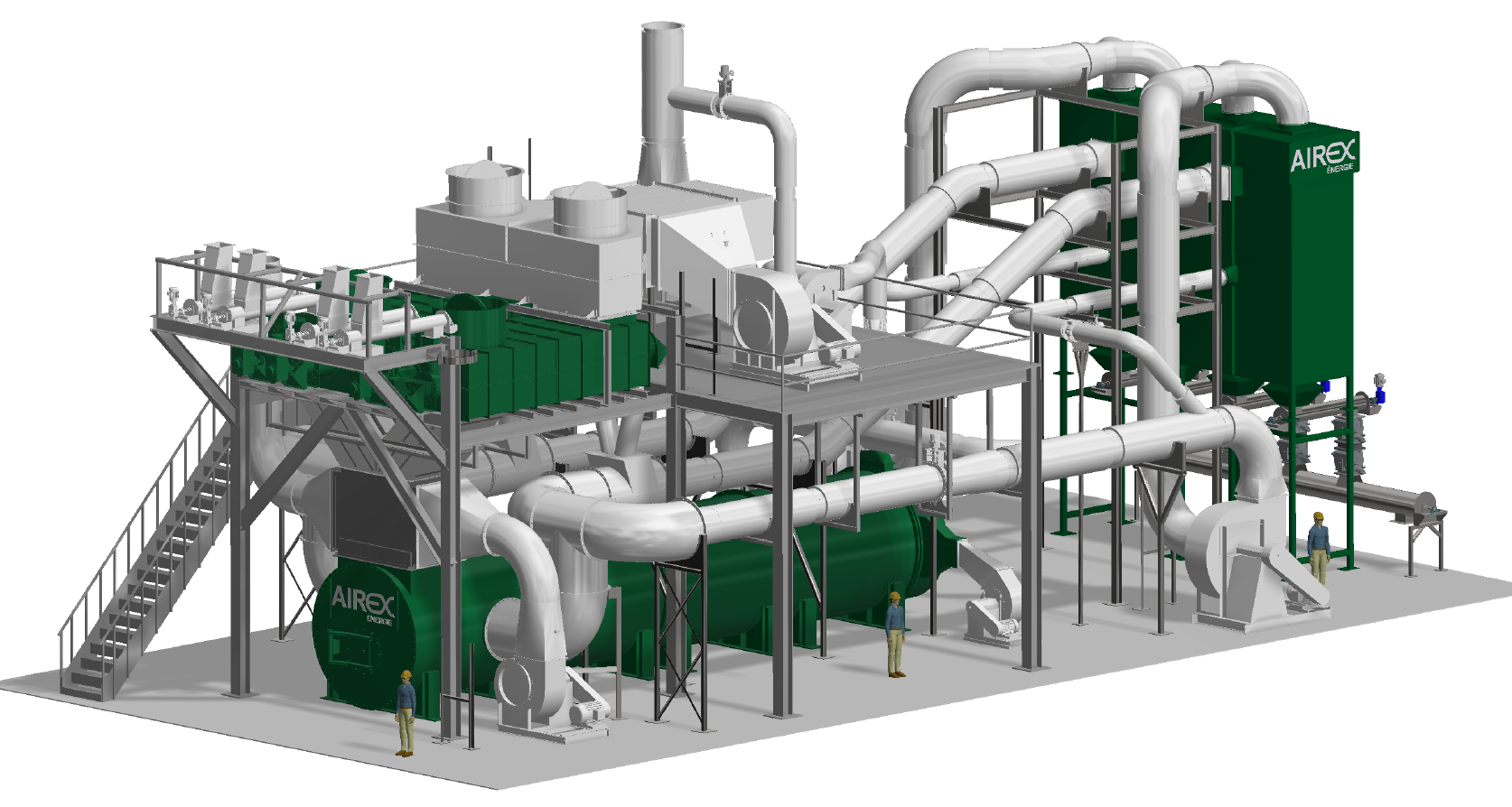

Conditioning chamber

Combustion chamber

Cyclonic reactors

The screw is heated by the combustion gas.

This heat enables the biomass circulating inside the screw conveyor to be heated indirectly, removing most of the moisture still present in the biomass after the drying proces

The combustion chamber acts as the thermal oxidizer of the CarbonFX system. Here, the recovered syngas is combusted with controlled air addition.

The resulting thermal energy is used to heat the conditioning chamber and supply hot gases to the cyclonic reactors. Any excess energy generated by the process is recovered and utilized for feedstock drying.

At the exit of the conditioning chamber, the biomass is entrained in a pneumatic conveying loop and is directed inside the cyclonic reactors.

Combustion gases are used to convey the biomass and are in direct contact with the biomass. The energy from the gases is transferred to the biomass, enabling the controlled pyrolysis of the biomass in absence of oxygen.

The torrefied biomass is then evacuated from the bottom of the cyclonic reactors through rotary valves.

Syngas generated during the torrefaction of the biomass is separated from the solids, evacuated at the top of the cyclonic reactors and redirected to the combustion chamber.

(~3 seconds)

| Model | CarbonFX™ |

|---|---|

| Technology | Torrefaction |

| Process Temperature (°C) | 350–450 |

| Operating Mode | Continuous |

| Heating Method | Direct |

| Reactor Type | Cyclonic |

| Output Product | Biocoal |

| Product format | Fine powder |

| Energy density (MJ/kg, db) | 18–23 |

| HGI | 21–38 |

| Input Production Capacity (kg/h, db) | 8000 |

| Output Production Capacity (kg/h, db) | >6000 |

| Yield | 75% to 80% |

| Scalability | Yes (modular) |

| Waste (Liquid or solid) | None |

| Process Automation | Advanced |

| Feedstock compatibility | Very flexible |

| Transportation & storage | Safe (non-hazardous) |

| Footprint size (L x W x H) | 32m x 15m x 11m (modular) |